Liquid Surface Treatments for Concrete – Quick Review

Objective

To better understand the function, selection and benefits of the broad types of liquid surface treatments for concrete.

Liquid surface treatments for concrete – overview

Liquid treatments come in two broad types:

- Penetrating – densifiers & impregnants

- Film-forming aka Topical – curing compounds, coatings & toppings

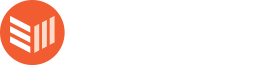

Densifiers & Impregnants

Concrete is a porous material. Penetrants (densifiers & impregnants) do their work here.

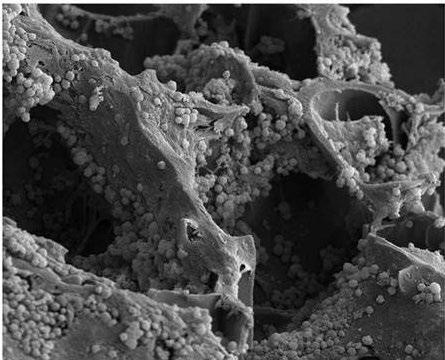

Coatings & Toppings

Densifiers

- 15% – 20% of the portland cement used in concrete forms into calcium hydroxide as a by-product of the hydration process

- This calcium hydroxide is rather soft and does not contribute to the structural strength of the concrete – it has virtually no value

- Liquid densifiers react with calcium hydroxide and harden, thereby strengthening the concrete surface

Quick summary

The silicate group – Sodium, potassium, magnesium, lithium

Colloidal silica group of products:

Silicate Densifiers

- Chemical hardening & densifying takes place over the course of 1 – 2 weeks, not in hours

- They are not curing compounds

- Should be applied to dry slabs

- Work down to ~ 3 mm max (depends on porosity)

Impregnants

Work by changing the surface chemistry of the top surface of the slab

- Generally, do not change the appearance

- Do not provide any additional abrasion or chemical protection

- Can provide stain protection

- May need to be re-applied from time to time

- EpiMax950

Product Selection Coatings vs Penetrants

Coatings

- mechanical protection

- chemical protection

- eliminate abrasion/dusting

- colour choices

- non-skid

Penetrants

- hardens surface => enable polishing (densifiers)

- stop water entry (impregnants)

Product Selection Coatings vs Densifiers

- Polished concrete surface grind issue

- Coatings: less than 80 -120 metal-bonded

- Densifiers: more than – 120 metal-bonded

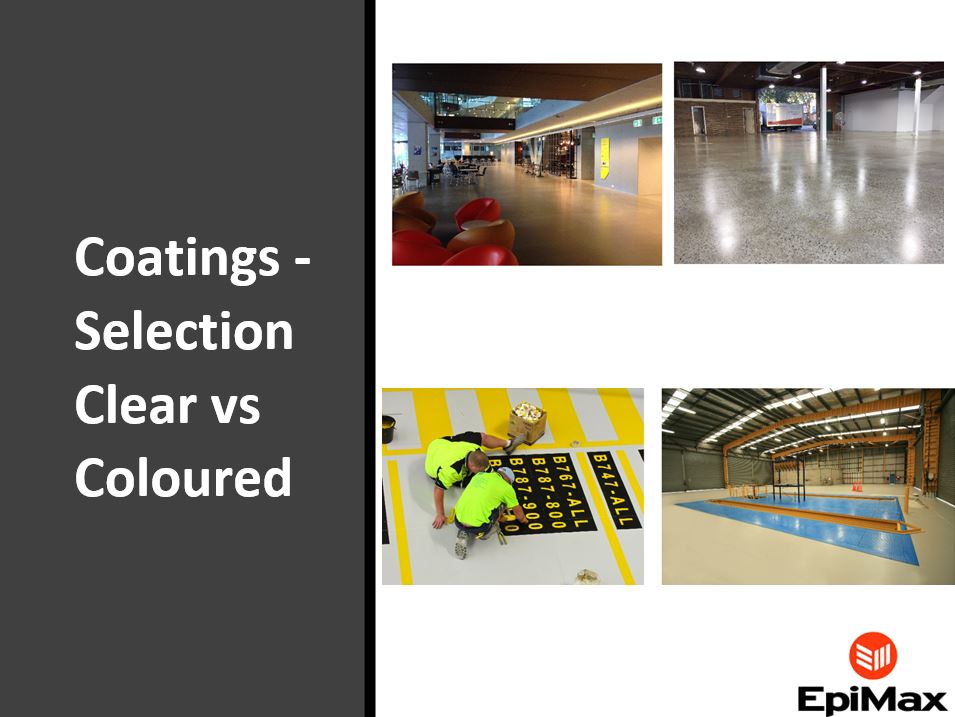

Coatings – Selection Clear vs Coloured

Clear

- Economy

- Can add architectural value

Coloured

- Brighten environment

- Gives greater architectural choice

- Delineate safety & hazards

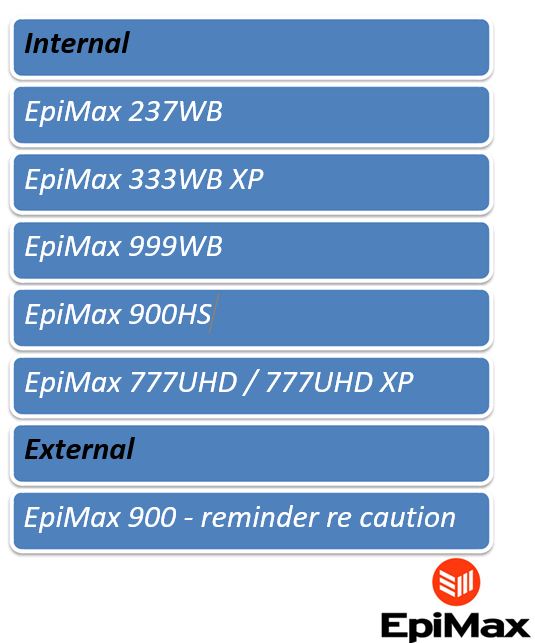

Coatings – Selection Internal vs External

Internal

- Widest choice

- Economy

External

- UV issue

- PU systems

Coatings – Selection Dry vs Wet

Dry

- Widest choice

- Economy

Wet

- Safety

- Anti-slip requirement BCA

Issues to watch out for

- Effect of temperature on work time

- Old slabs & osmosis potential

- Cutting – in with colours

- Joints

CATEGORIES

Knowledge value at your fingertips

SIGNUP NOW

Signup to the Knowledge Centre.