Maximising long term architectural appeal…

What needs to be considered for polished concrete finishing products?

Proven performance

High end polished concrete finishes can be a time-consuming process. Any products used in the overall process must a have proven track record. They should take advantage of new developments, but they must be tested in the real world before distribution into the wider market.

Consistent results

Consistency is the holy grail of application work. All slabs will vary, but some products just work better, whether they be concrete coatings or densifiers.

Concrete is 85% sand and aggregate, and the balance, 15% is portland cement.

During the curing of the concrete, it has been estimated that only 20% of the portland cement is converted to calcium hydroxide.

So, in a fully hydrated slab, only 3% of the slab is available to convert into calcium silicate hydrate through the use of any silicate densifier.

And yet, just 3% of the slab contents, with the correct densifier and application technique, can improve the abrasion resistance by up to 40%.

Provide the target architectural appeal

ST115 is a new standard for the concrete polishing industry that has been adopted by the Concrete Sawing and Drilling Association (CSDA). The standard explains in detail how to measure the texture of a concrete surface by using a texture meter.

The standard assigns a numerical texture-grading code to the finish so the design community and end-users alike can begin to have a more structured conversation about the quality and sustainability of a polished concrete surface. It can also be used to determine if steps in the polishing process were skipped or avoided.

Sustainability – the whole of life

Sustainability is related to the quality of life in a community – whether the economic, social or environmental systems that make up the community are providing a healthy, productive, meaningful life for all community residents, present and future.

With regard to protection systems, sustainability should consider the “whole product life cycle”. This includes production, application, service life and disposal.

Volatile Organic Content (VOC) is an important measure of a protection system’s environmental impact.

Our products meet or exceed the requirements of IEQ.13.1, Green Star Office Interiors, Indoor Environment Quality. We are a member of the Green Building Council of Australia.

Design life – budget compliance

The first important question to ask when selecting a new protection system is – What is the required design life – 2, 5, 10 or 20 years? And, is frequent or regular maintenance feasible?

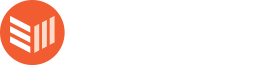

Polished concrete flooring

Is a generic term covering a variety of decorative concrete flooring options that often leaves the concrete surface exposed as the final floor finish?

Polished concrete is available in a wide range of colours and finishes and is energy efficient. Suitably protected, it is low maintenance and dust-free.

It has become very popular in commercial and residential settings.

EpiMax has built its reputation on a construction engineering foundation. Our experience has been forged on an impressive variety of civil, environmental, industrial, mining, defence and general services construction.

This success has been proven through partnerships with forward-thinking architects, consultants, engineers, application contractors, project managers and materials testing agencies. We believe in teamwork, respect and integrity.

Our primary focus is:

- Floor Protection Systems

- Industrial Concrete Protection Systems

- Green Star Protection Systems

- Water and Wastewater Processing Protection Systems

- Foundation Protection Systems

- Extreme CAT (Corrosion, Abrasion and Thermal) Protection System

How do silicate concrete hardeners differ?

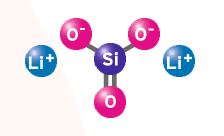

Lithium silicate chemical hardeners for polished concrete work are becoming more popular than sodium or potassium silicates.

Why is this?

Background chemistry

The function of the sodium, potassium, or lithium part of the silicate’s function only is to stabilise and solubilise the silicate so it can remain in solution until it penetrates the concrete and then can react with the abundant calcium hydroxide found in the concrete pores and canals.

Advantages of lithium silicates

Lithium ions on a weight basis can stabilise more silicate ions than sodium or potassium ones. Lithium silicates generally have a lower viscosity than sodium or potassium at equal solids.

So, lithium silicate can penetrate more effectively

What is the lithium silicate chemical reaction?

5CaO • H2O + Li2O • 5SiO2 => 5CaO • SiO2 • 2H2O + Li2O • H2O

Calcium + Lithium => Calcium + Lithium Hydroxide Silicate Silicate Hydrate Hydroxide

Our Range of Products:

- EpiMax 2125

- EpiMax 2135/EpiShine

- EpiMax 2150

- EpiMax 2175

- EpiMax 3500

- EpiMax 777UHD

- EpiMax 900

- EpiMax 950

- EpiMax 999WB

Applications – Residential:

- High-end polished concrete

- Garages, sheds

- Driveways and stonework

Applications – Retail:

- High-end polished concrete

- General shop fit-out flooring

- Restaurant dining areas

- Factory outlet stores

- Wholesale warehouses

- Stock rooms

- Plant rooms

- Commercial kitchens

- Showrooms

Applications – Commercial and Industrial:

- Medium level polished concrete

- Plant rooms

- Showrooms

- Stock rooms

For more information on any of our polished concrete finishing products please contact us today.

CATEGORIES

Knowledge value at your fingertips

SIGNUP NOW

Signup to the Knowledge Centre.