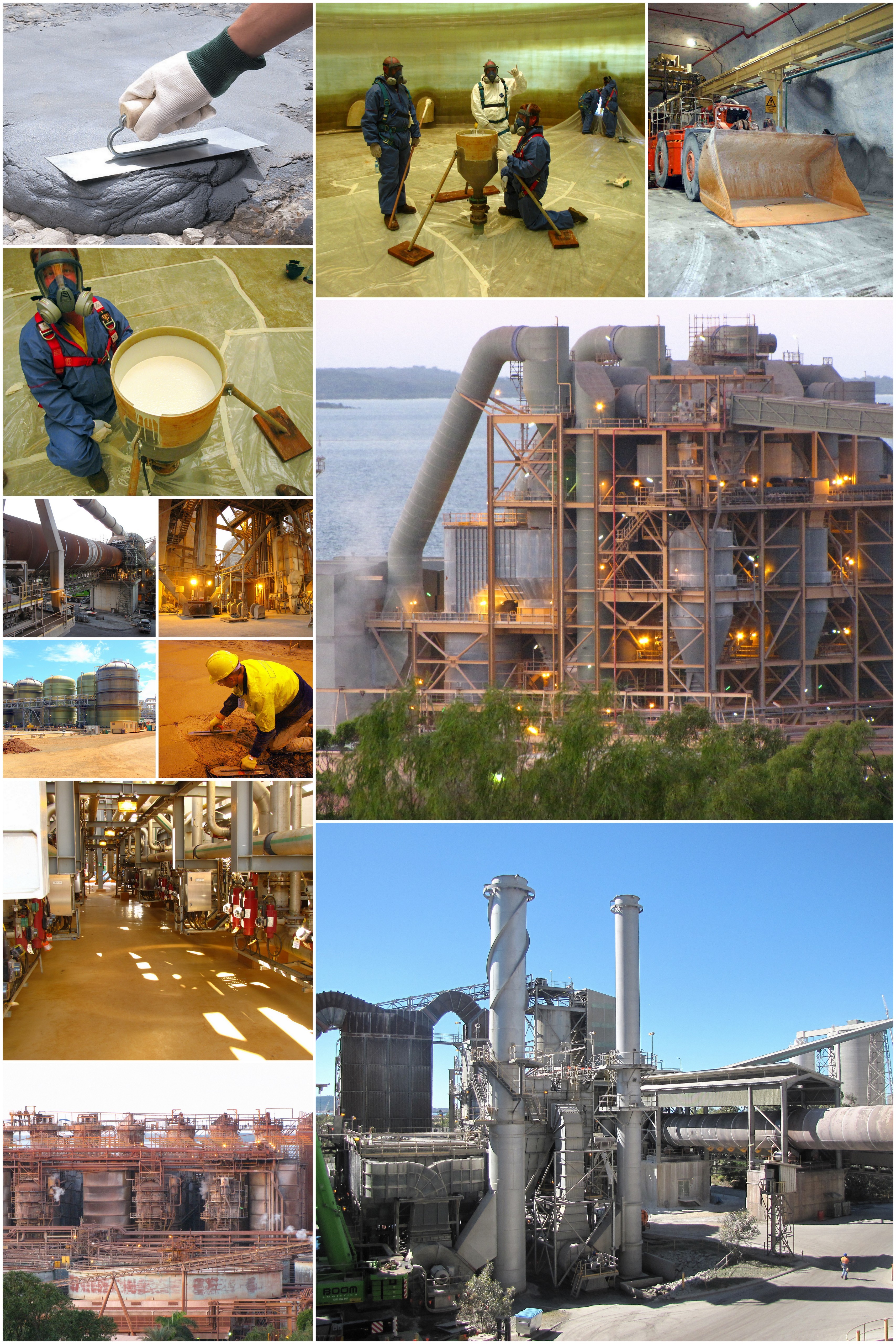

Concrete Protection Harsh Environments

EpiMax offers proven systems for steel protection in the abrasive, highly acidic condition to 600 C.

About extreme environments

Concrete and steel structures in the resources and heavy industry sector are subjected to some of the harshest environments known. Many structures in these industries must resist a powerful combination of forces including those of chemical, abrasive impact and thermal action. Processing chemicals can easily penetrate porous, unprotected concrete surfaces. Corrosive chemicals will quickly attack mild steel.

Leaks, splashes, and or spill onto floors, drains, bunds, walls or other infrastructure, will cause premature failure. In addition, chemicals can pass through concrete slabs into the soil below, eventually reaching groundwater under the facility.

Abrasive impact causes rapid damage. Wear on concrete floors, due to lift truck activity, skidding, scraping and sliding is abrasive. It causes a breakdown of the concrete leading to the formation of further abrasive particles which accelerate the damage. High temperatures accelerate the chemical deterioration of concrete.

Extreme environments benefits

- Resurface and protect concrete subject to high acid exposure

- Benefit from the highest performance in a field applied coating system