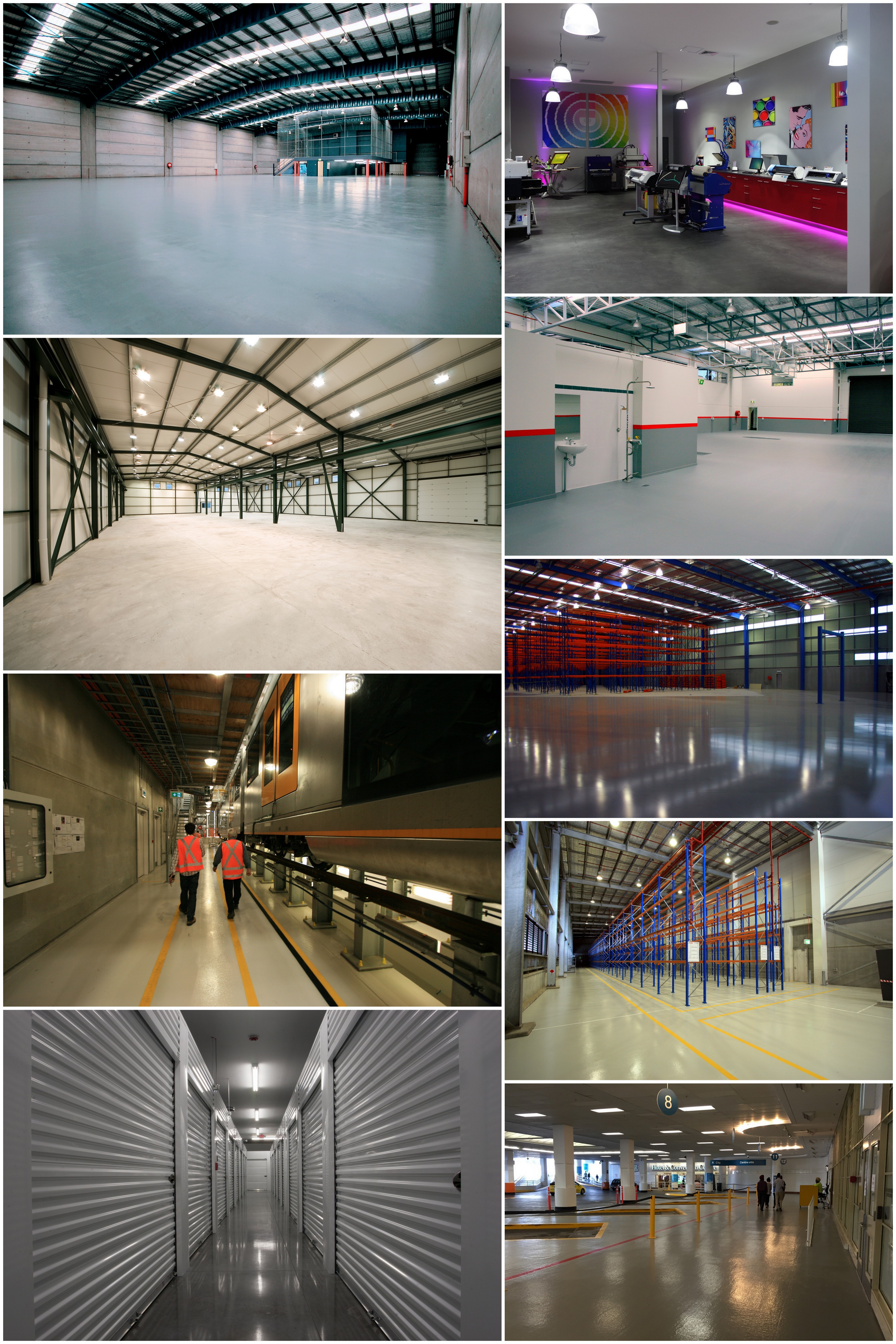

About general flooring

All operations within any facility are connect by the working floor.

Originally, the protection of concrete floor space was virtually non-existent, but over the past 4 decades the focus has shifted to protecting concrete floors, with sophisticated processes developed to provide a protective coating or surfacing.

Concrete Floor Protection

So, why protect concrete floors? The main reason is to protect the concrete structure from deteriorating or becoming contaminated. Other reasons include providing slip or chemical resistance, ease of cleaning and maintenance, better physical performance, aesthetics, durability and much more.

Whether industrial or commercial, there is no other surface in a building or structure that has to endure the wear and tear and abuse a concrete floor goes through. Gravity, along with poor housekeeping and heavy duty actions upon the floor, are the drivers of abuse in these busy environments.

Why protect your concrete floor surface?

Just some of the regular abuse commercial and industrial floors are subjected to include impact, thermal shock, abrasion and attack from chemicals. While concrete is robust, it’s not impervious to abuse and isn’t designed to withstand abuse on a continual basis. Also, because concrete floors are porous, wear and tear on them tends to create dust. As mentioned, they are also regularly subjected to abrasion and chemical attacks.

No matter where it is located, all concrete floors need added protection to protect the surface and to ensure longevity and safety. The problem is determining what type of floor protection will work best for a particular environment or different conditions. Not all concrete floors are the same and neither are all working conditions the same.

How do we get it right?

This is what the selection process comes down to:

- Service conditions need to be evaluated to define physical requirements

- Evaluation of the concrete floor is necessary to determine its age, joints, strength and overall integrity

- Other issues need to be considered – aesthetics, maintenance-free periods, budget and application parameters

- Then, an appropriate flooring system can be selected

- Select a competent applicator

General flooring benefits

- Significantly safer, cleaner working environment

- Protection of the base slab from mechanical abuse

- Protection of the and chemical deterioration

- Brighter, lighter working environmemt

- Reduced cleaning costs

- Significantly increase floor surface lifespan

Download information

- UK Health & Safety Executive Mapping Tool

- EpiMax 333 CSIRO Slip Test Report

- Standard colours to AS 2700-2011 supplied as Colourpacks or Pre-Tinted for larger projects

- Concrete protection in the wine making environment

- Slab protection in warehousing & distribution

- Food and Beverage Facility Protection Systems

- Water and Wastewater Facility Protection Systems

- Commercial Kitchen Floor Protection Systems

- Concrete Care Reference Guide

- Waste Processing and Recycling Facility Protection Systems

- Precision Grouting and Repair Systems

- Museum and Archive Floor Protection Systems

- Oil, Gas and Chemical Protection Systems

- Sugar Processing and Storage Protection Systems

- Performance Interior Wall Protection Systems

- Low VOC Performance Protection Systems

- Resources and Heavy Industry Protection Systems

- Automotive Service and Repair Facility Protection Systems

- Healthcare and Pharmaceutical Facility Protection Systems

- Aerospace and Aviation Floor Protection Systems

- Mass Transit Service Facility Protection Systems

- Warehouse and Distribution Centre Floor Protection Systems

- Parking Facility Floor Protection Systems

- Education and Learning Facility Protection Systems

- Retail and Commercial Floor Protection Systems

- Studio and Showroom Floor Enhancement Systems